welcome to leizhan.

welcome to leizhan.

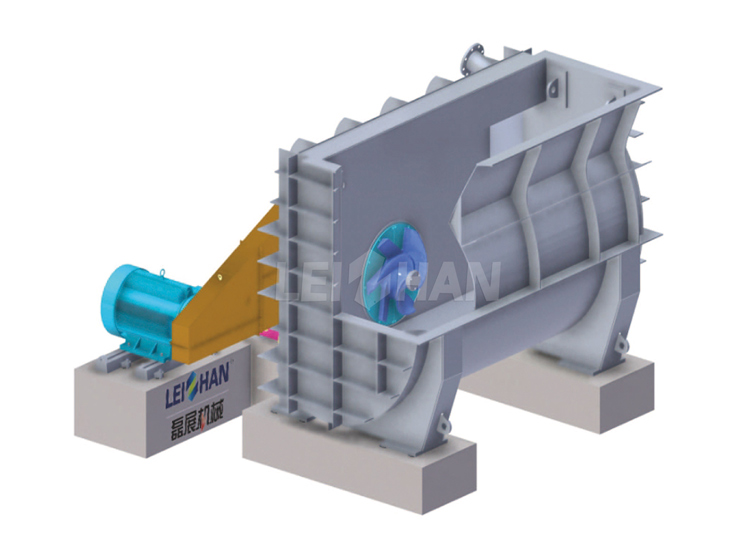

Mainly used for broken paper treatment from press section, calender, paper reel section, etc.

1. Mainly used for broken paper treatment from press section, calender, paper reel section, etc.

2. Optimized rotor shape for higher turbulence at the lowest power consumption.

3. High pumping efficiency greatly increases the friction between the fibers-not only relying on mechanical forces between rotor and screen plate for pulping disintegration.

|

Model |

SZS1 |

SZS2 |

SZS3 |

|

Rotor Dia.(mm) |

Φ750 |

Φ1000 |

Φ1300 |

|

Width of the chest(mm) |

2500-5000 |

3500-6000 |

4500-8000 |

|

Pulp consistency(%) |

3-5 |

||

|

Screen hole size(mm) |

10-24 |

||

|

Motor power(KW) |

45-160 |

90-355 |

200-630 |

You can contact our head-office directly, also you can mail to us. Of course, free live-chat is available and you can get help immediately.